Factory architectures

Factories of the future need software architectures capable of seamlessly exchanging data across machines and applications. Unfortunately, today’s ad hoc and tightly coupled legacy systems can prove limited. That’s why GTMI has developed a Decoupled Digital Architecture, a high-performance, low-cost, standards-based leap ahead of current legacy systems.

Machine communication

GTMI is a leader in streamlining communication with machines on the shop floor. We develop solutions that address the wide variety of protocols used by manufacturing equipment, PLCs, SCADA applications, MES and ERP systems. GTMI has also helped develop key industry standards, including MTConnect and Computer Aided Manufacturing using XML (CAMX). We have vast experience interfacing to equipment and manufacturing applications using protocols such as OPC-UA, Modbus, ROS and SECSII/GEM.

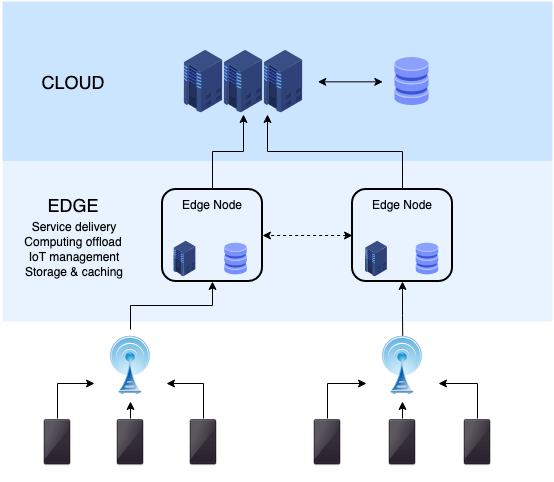

Cloud computing

Cloud computing is swiftly transforming manufacturing by providing unprecedented access to innovation, software, services and infrastructure. GTMI develops and deploys cloud solutions in an array of areas, including machine learning, Internet of Things, stream analytics, high-speed processing of data, load balancing, standardized architectures, optimal data storage and presentation. We can help you navigate the myriad of cloud services and vendors to reduce costs and enhance success.

Edge devices

GTMI is at the forefront of developing edge devices capable of high-speed data sensor gathering, enabling enhanced hardware and software development and smarter decisions. We know how to install edge devices within machine tools and work cells to efficiently collect, analyze and transmit manufacturing process information, empowering quick process improvements without the need to transfer large amounts of raw data.

Cybersecurity

GTMI actively leads research into methods, techniques, standards and software to enhance the security and resilience of manufacturing systems and the supply chain. As technology and equipment are added to supply chains, security vulnerability grows. Cybersecurity has become a significant cost driver, and many manufacturers struggle to know what to do next. We can help. For example, GTMI’s Center for Biomanufacturing Cybersecurity and Resilience (CBCR) focuses on achieving secure, resilient and competitive biomanufacturing.

Machine learning and artificial intelligence

The massive growth of Machine Learning (ML) can transform data processing and deliver exceptional insight into processes and operations. GTMI applies new analytic techniques, software libraries and hardware platforms to solve problems that have long frustrated manufacturers. And we go beyond concept to application. Our diverse array of industrial equipment allows us to run experiments to verify ML algorithms, ensuring successful deployment.

Overall equipment effectiveness (OEE)

GTMI offers the expertise you need to leverage OEE for your factory assets, delivering accurate data that can be reliably used for comparison, benchmarking and decision-making. OEE analyzes and compares machine utilization with machine throughput, part quality and performance relative to schedule. Since OEE calculations require data from multiple systems (e.g., machine, quality, MES, ERP, scheduling), our advanced knowledge of those systems is critical.

Predictive maintenance

GTMI can help you minimize the guesswork of scheduling maintenance by implementing a predictive approach to maintenance. Maintenance routines are often based on the calendar, rather than on true need. Unfortunately, that means parts can be replaced too soon (wasting usable life and causing machine downtime) or too late (resulting in unplanned outages). Our approach to predictive maintenance allows manufacturers to monitor part performance and perform maintenance when degradation is detected, paving the way for reduced downtime, cost and risk.